About Us

3DP Technologies – A 3D printing product and Service company established in Noida. With a several years of experience in additive manufacturing and design field, our team constantly strive to build the 3D printing and other manufacturing technology & its eco system in India with our industry expert team. We believe in complete customer satisfaction with quality and timely delivery of projects.

In recent times, 3D printing has evolved quickly as a tool to develop prototype and personalized goods. But as the technology is being too exposed to the market, the choice of selecting a reliable partner becomes a key factor. We at 3DP technologies not only offers the high level of customer satisfaction but we also offers the flexibility to gain personal experience to our clients to printing in real.

We also deals with reverse engineering services where we offers complete project starting from scanning to design. Our experts are widely involved in product design along with simulation which gives you an upper hand while developing a competitive product and save time to market.

Our organization is made up of all of the life experiences each employee has brought. Located in the industrial hub always has the advantage to enjoy and learn from the other organization.

Vacuum Casting

Polyurethane vacuum casting is a method for making high quality prototypes or low volumes of parts formed from inexpensive silicone molds. Copies made in this way show great surface detail and fidelity to the original pattern.

• Low cost for molds

• Molds can be made in a few days

• Many types of polyurethane resins are available for casting, including overmolding

• Cast copies are highly accurate with excellent surface texture

• Molds are durable for 20 or more copies

• Perfect for engineering models, samples, rapid prototypes, bridge to production

Soft Tooling

Rapid Prototyping Tooling/Parts :- : (Proto Soft Tooling)

A. Special Design Arrangement for Plastic Soft tools

B. 2 Plate construction, manual sliders along with Secondary operations: - Welding, Hot/Cold inserts assembly.

C. Part molding for low volume Production

D. Machined Proto parts in AL, Plastics, Metal (VMC Machining)

E. Fabricated sheet Metal parts.(MS or AL or SS).

F. Rubber Sealing (Soft tooled molded ).

G. Welding & Fastener assy. Etc.

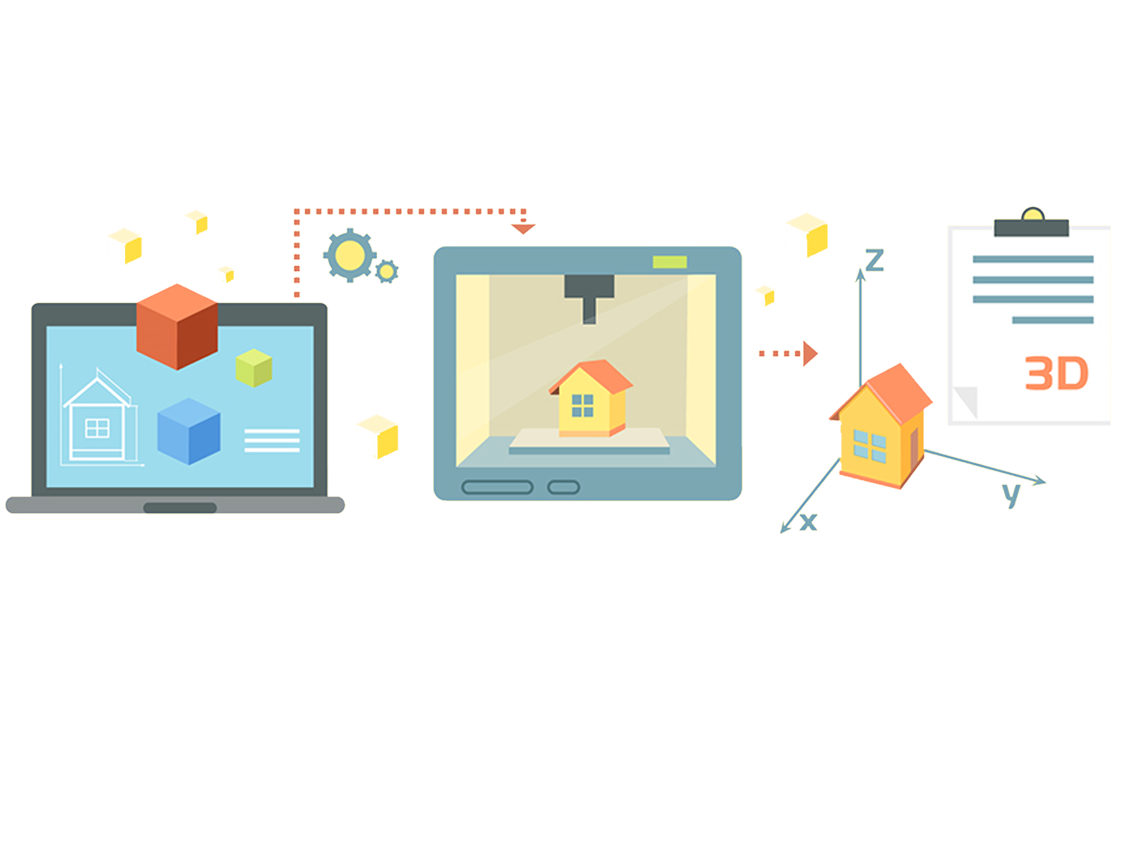

Product Design & Reverse Engineering

Design is the first step to bring your idea to life. Our expert modelers and designers can create high quality designs after carefully understanding your requirements.

We have designed and created 3D Models for engineers, architects, product developers, automobile companies, IOT and wearable start-ups.

Whether you require complete design for your product from scratch, or need your 2D Drawings to be converted into 3D Models, we do it all.

We also offer Reverse engineering solutions which is very common in such diverse fields as software engineering, entertainment, automotive, consumer products, microchips, chemicals, electronics, and mechanical designs.

It can be said that reverse engineering begins with the product and works through the design process in the opposite direction to arrive at a product definition statement. In doing so, it uncovers as much information as possible about the design ideas that were used to produce a particular product.